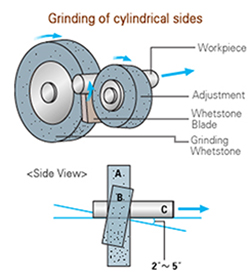

In thrufeed centerless od grinding the workpiece passes between two wheels a grinding wheel and a regulating wheel as illustrated in the diagram right.

Centerless grinding machine line diagram.

The centerless process is commonly used for high volume production and it s also easily used for low volume production because the machine setups are fairly simple.

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece.

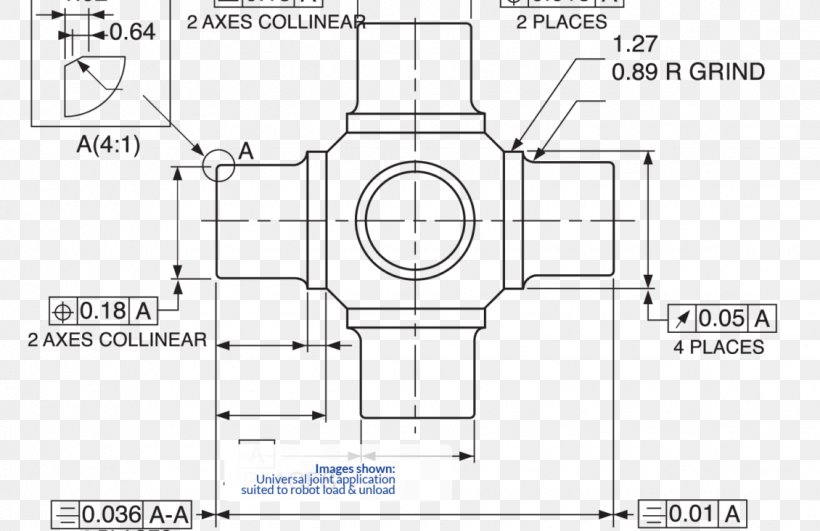

Cylindrical grinding machine line diagram.

Centerless grinding differs from centered grinding operations in that no spindle or fixture is used to locate and secure the workpiece.

High precision automated infeed thrufeed centerless grinding machine.

In thrufeed centerless od grinding the workpiece passes between two wheels a grinding wheel and a regulating wheel as illustrated in the diagram below.

Tool and cutter grinder machine.

Multiple machines can be linked to do rough medium and fine grinding in one production line to save time for repetitive loading and unloading procedure.

Centerless grinding machines are often classified according to the inclination of the machine bed.

Centerless grinder with 700mm wide wheel for heavy work such as crankshaft journal grinding.

Tool manufacturing and tool resharpening.

Found at the highest end of the gt 610 series spectrum the gt 610 cnc high precision automated infeed thrufeed centerless grinding machine excels at grinding a wide range of materials and is the complete lights out solution for applications where a high degree of automation data gathering and gauging feedback is.

The centerless process is commonly used for high volume production and it s also easily used for low volume production because the machine setups are fairly simple.

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece centerless grinding differs from centered grinding operations in that no spindle or fixture is used to locate and secure the workpiece the workpiece is secured between two rotary grinding wheels and the speed of their rotation relative to each.

Blade selection due to different working diameters the guide plate and regulating wheel must be parallel as this influences the grinding accuracy significantly.

The workpiece is secured between two rotary grinding wheels and the speed of their rotation relative to each other determines the rate at which material.

Tool grinding may be divided into two subgroups.

There are many types of tool and cutter grinding machine to meet these requirements.

Although centerless grinding is a mature process today s grinding machines are equipped with newer features that enhance performance.

For example cnc programmable controls increase process efficiency and productivity by making it even easier to set up and change the equipment from one job to the next.

Types of internal grinding machine with diagram explained.

Horizontal bed machines are the most common as they provide easy accessibility during wheel dressing.